ORTHOPÉDIE CHABLOZ

Chabloz Orthopédie excels in made-to-order orthotics, prosthetics, and other orthopedic devices, such as helmets for babies with plagiocephaly, myoelectric prostheses, upper and lower limbs prostheses for everyday use, and several types of equipment.

Chabloz collaborates with rehabilitation specialists across France to produce the most effective functional orthopedic alternatives for patients and their families. Chabloz is owned by a German prosthetics manufacturer by the name of Ottobock. It aims to expand its market reach to more French regions and countries globally.

For more, please click here.

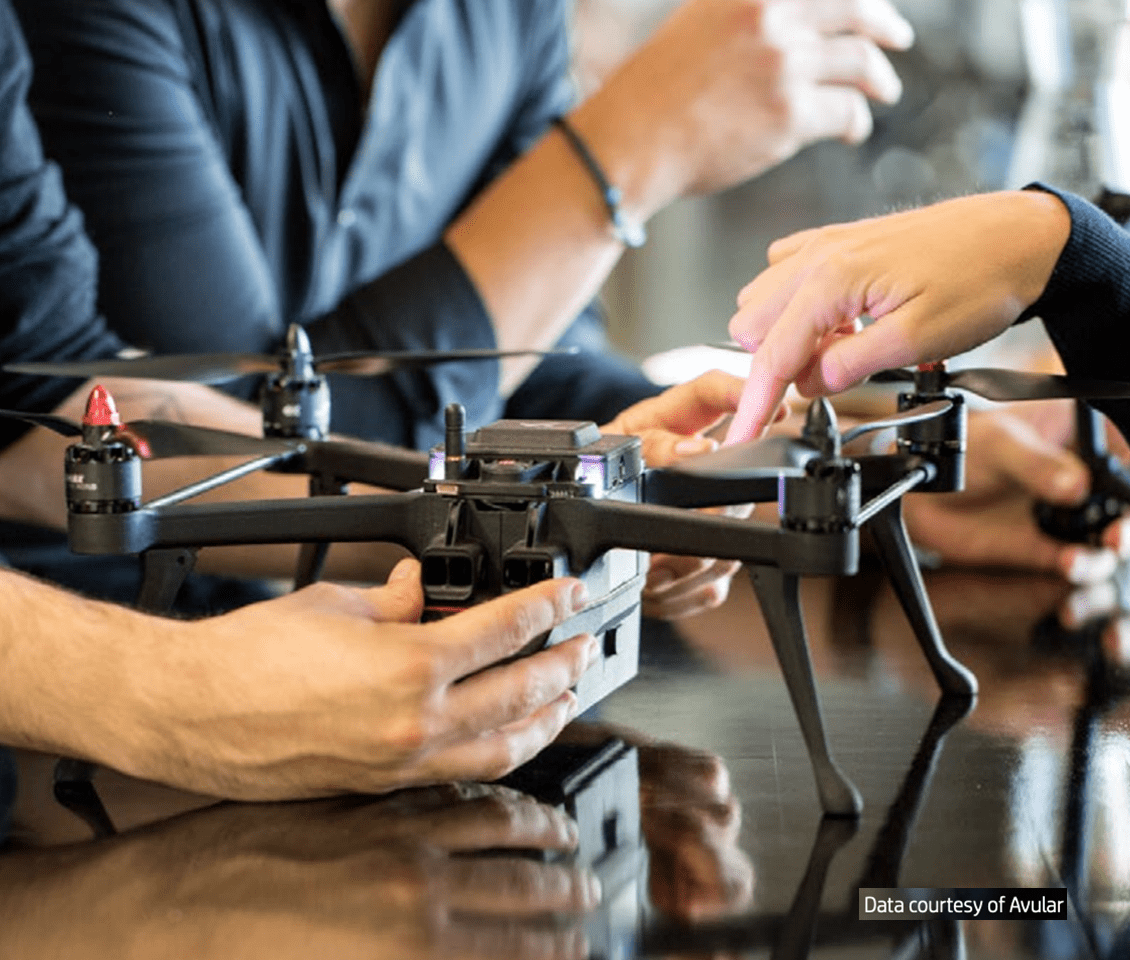

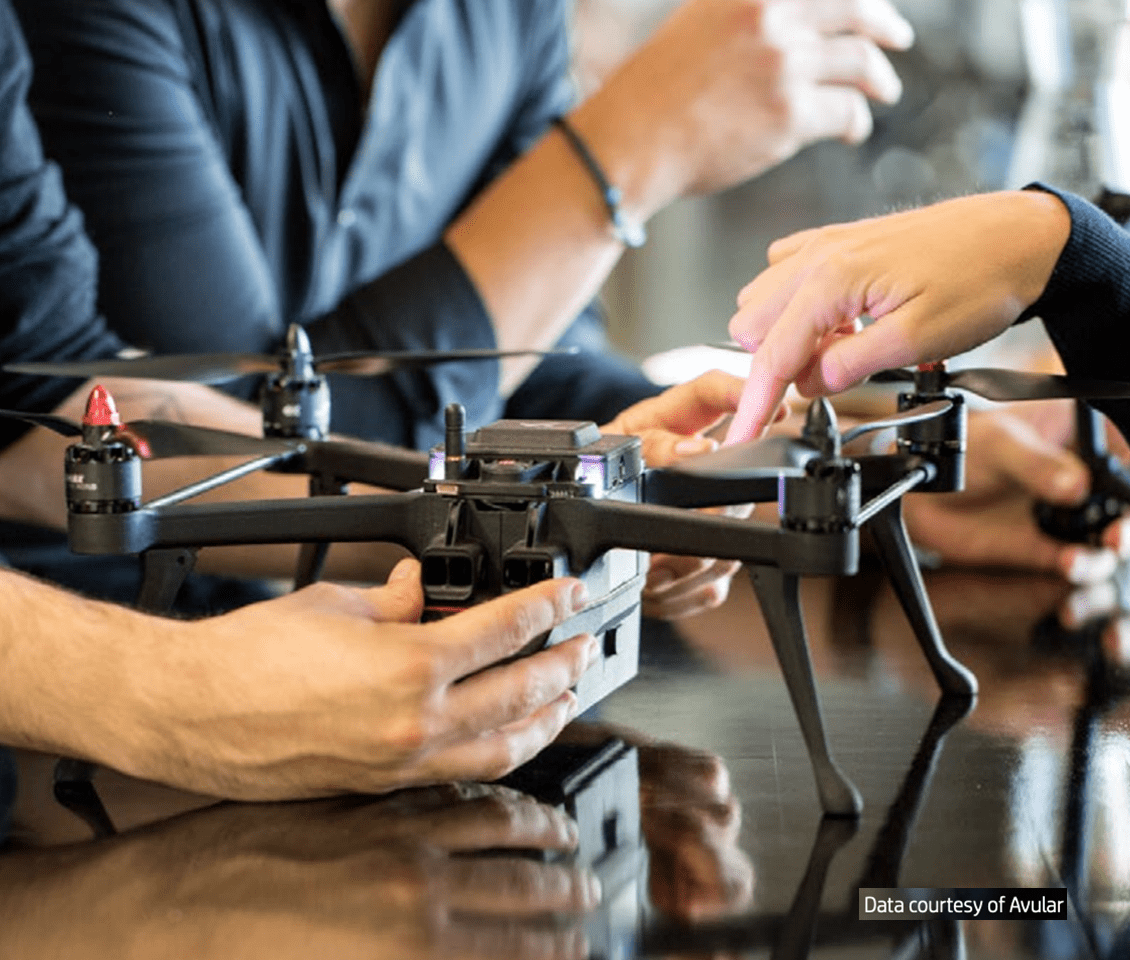

AVULAR & MATERIALISE

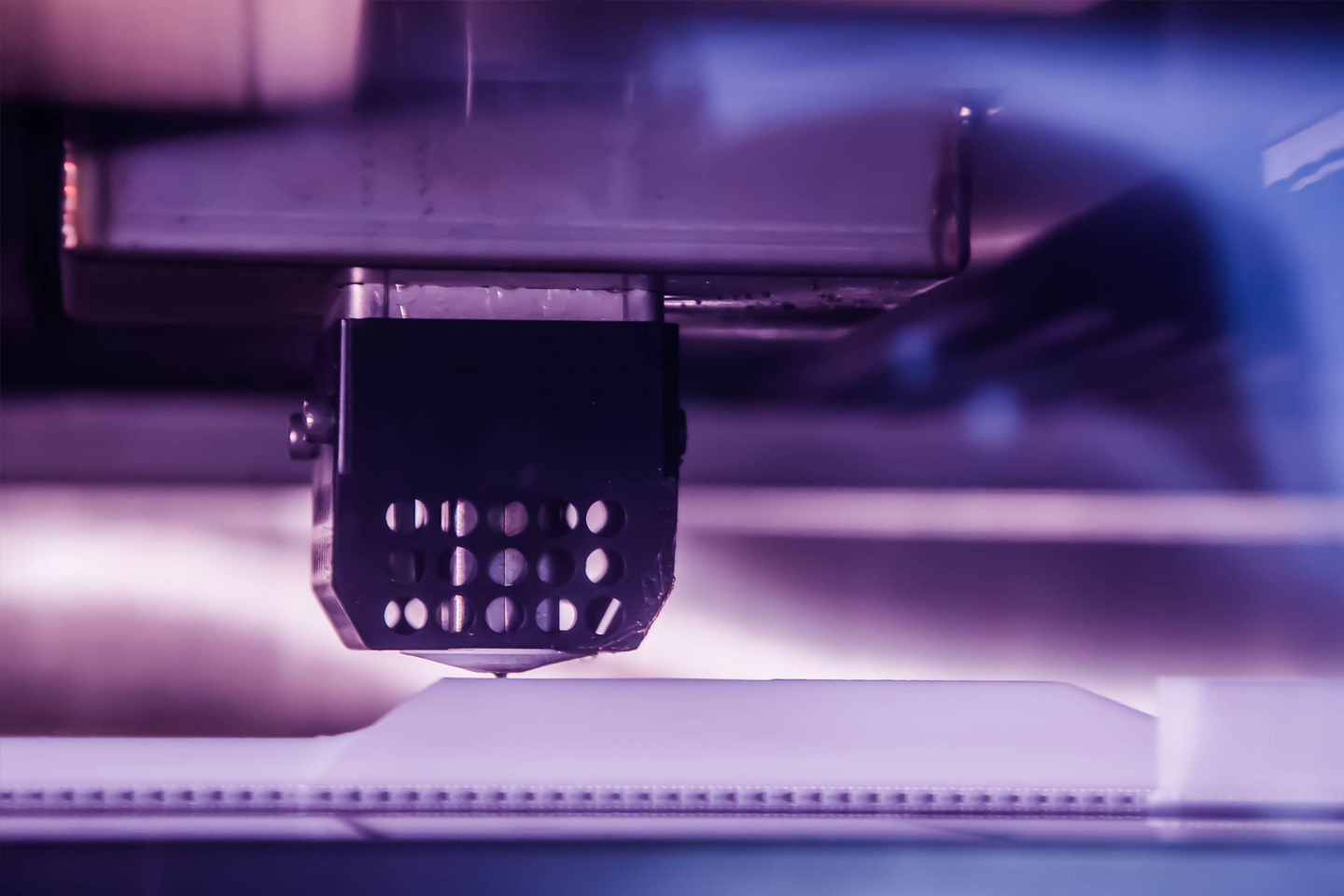

Avular employs 3D printing extensively for the manufacture of various components of their products and prototyping. They can incorporate hollow spaces, PCB holders, battery holders, a clicking mechanism, and wiring guides its 3D printing technology, which would have been way more challenging with other production methods. With an on-demand production strategy, Avular makes maximum use of its 3D printing's design flexibility to make changes to drone designs when demanded by the client.

For more, please click here.

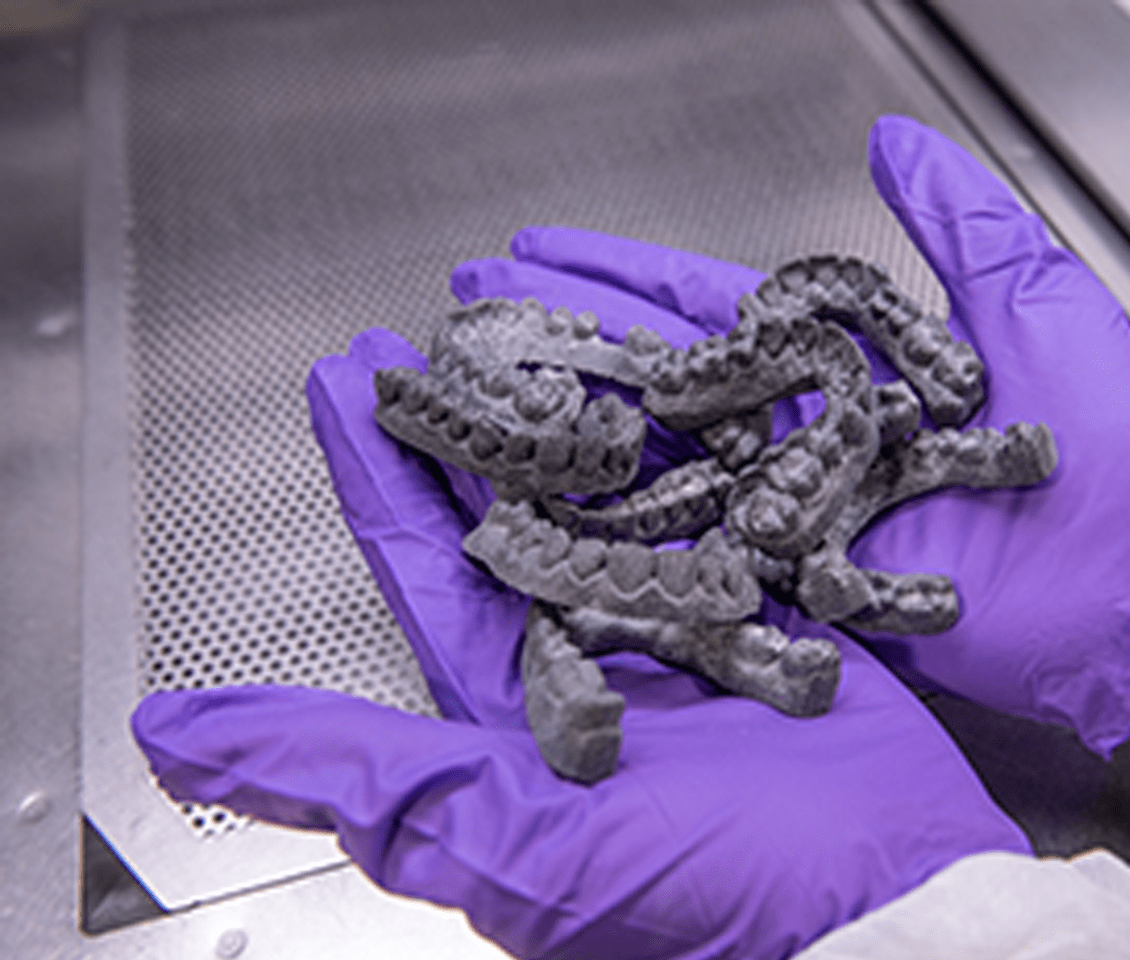

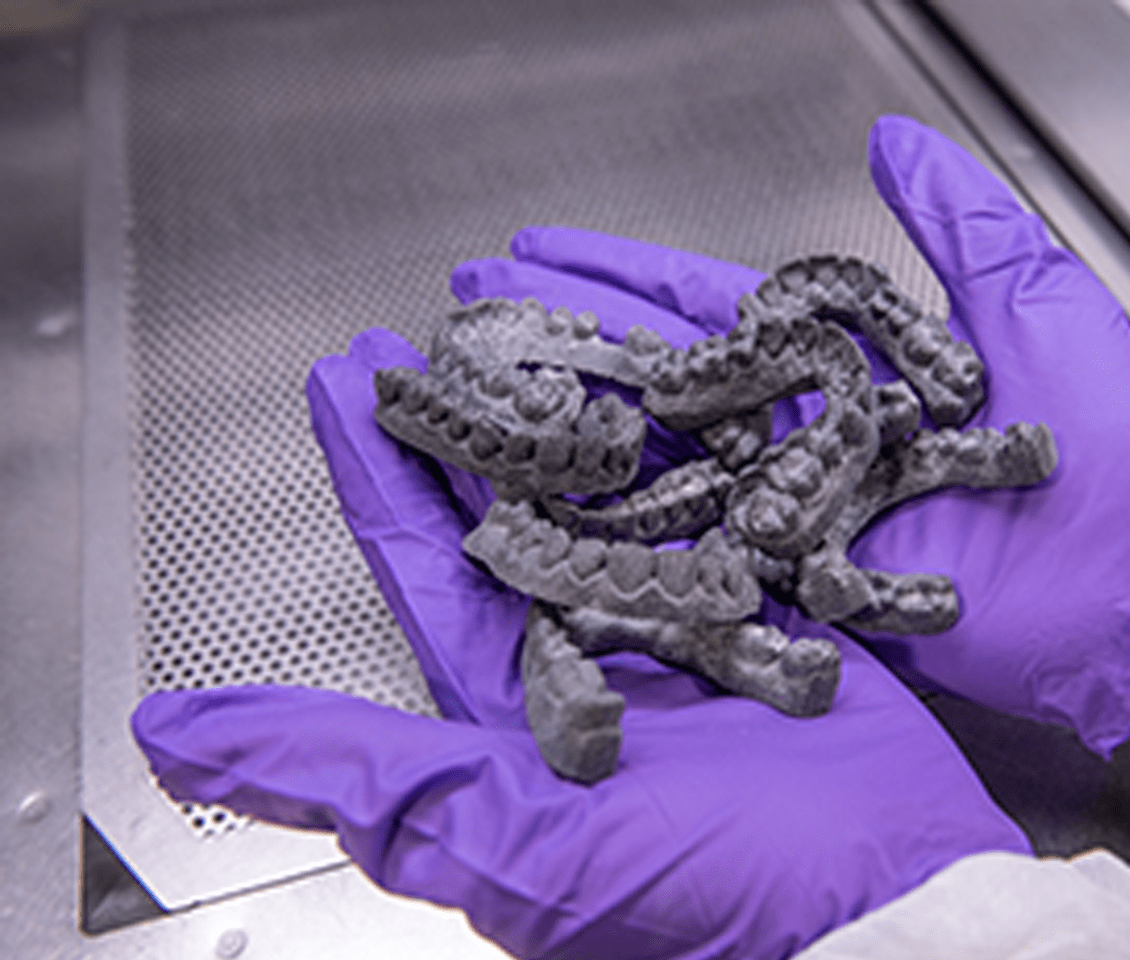

CLUB SMILE DIRECT

SmileDirectClub is the world's first telehealth platform for the alignment of teeth to transform your smile. SmileDirectClub is transforming the dental care market with its vertically integrated approach and state-of-the-art teledentistry technology.

SmileDirectClub was founded in 2014 and has become a pioneering teledentistry platform that connects those in need with a network of more than 250 locally licensed orthodontists and dentists who use the cutting-edge technology of SmileDirectClub to prescribe and monitor clear aligner therapy remotely, costing them 60% less than traditional braces. Up till now, SmileDirectClub has successfully helped more than 750,000 people from three continents in regaining their confidence with a perfect smile.

For more, please click here.

SKORPION ENGINEERING

Alvaro Dal Farra, a freestyle motorcycle rider, wanted to customize his Kawasaki KX 450 3D Core motorcycle by adding functional features like a customized fuel tank and fairing. Skorpion Engineering, using its HP Multi Jet Fusion (MJF) technology, successfully designed and printed these parts in a 3D format. A racing motorbike needs to be strong enough and should have mechanical qualities to withstand the sharp turns of a race.

For more, please click here.

MEIDAI

Hangzhou MEIDAI Technology Co., Ltd, commonly known as MEIDAI, is a fashion technology firm offering customized and comfortable products to trend-conscious and fashion lovers globally. With over ten years of experience in the field, the founders of MEIDAI specialize in manufacturing and bringing forth modish and elegant eyewear to their customers via their website.

Earlier, MEIDAI used to make eyewear using standard manufacturing processes. However, they soon realized that it wasn't the most cost-effective approach to manufacture. As a result, to achieve a low cost per part, MEIDAI had to sacrifice quality and had to invest in molds, tools, and other equipment needed to secure a return on investment to continue manufacturing in the long run.

For more, please click here.

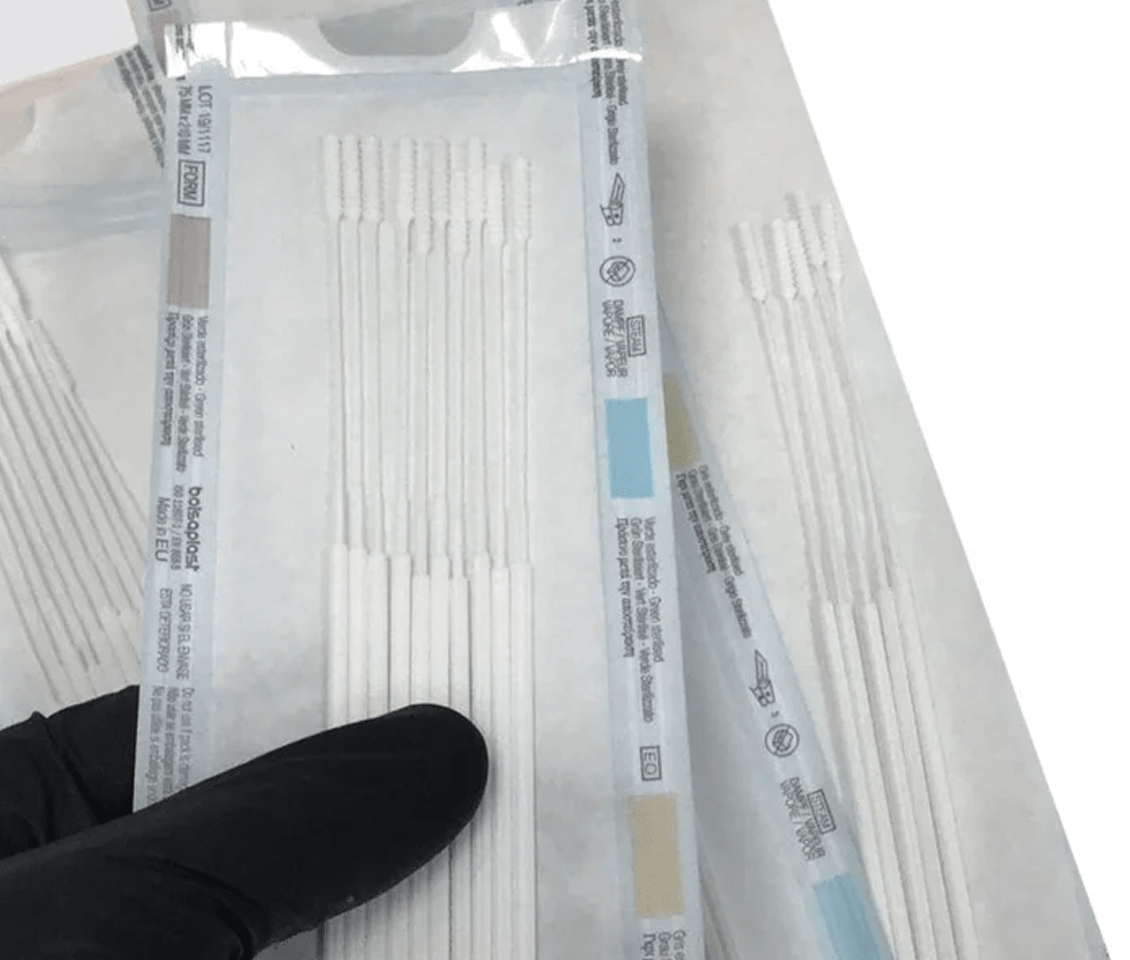

Nasal Swabs FROM AN AENIUM Burl oak-Certified 3D-Printer

The COVID-19 pandemic took the world by storm by putting the healthcare systems to the test. Supply networks were disturbed, necessitating agile, local medical solutions. To combat the shortages of medical supplies, several companies contracted with local authorities to provide key medical products such as face mask filters, ICU supplies, ventilators, and many others.

For more, please click here.

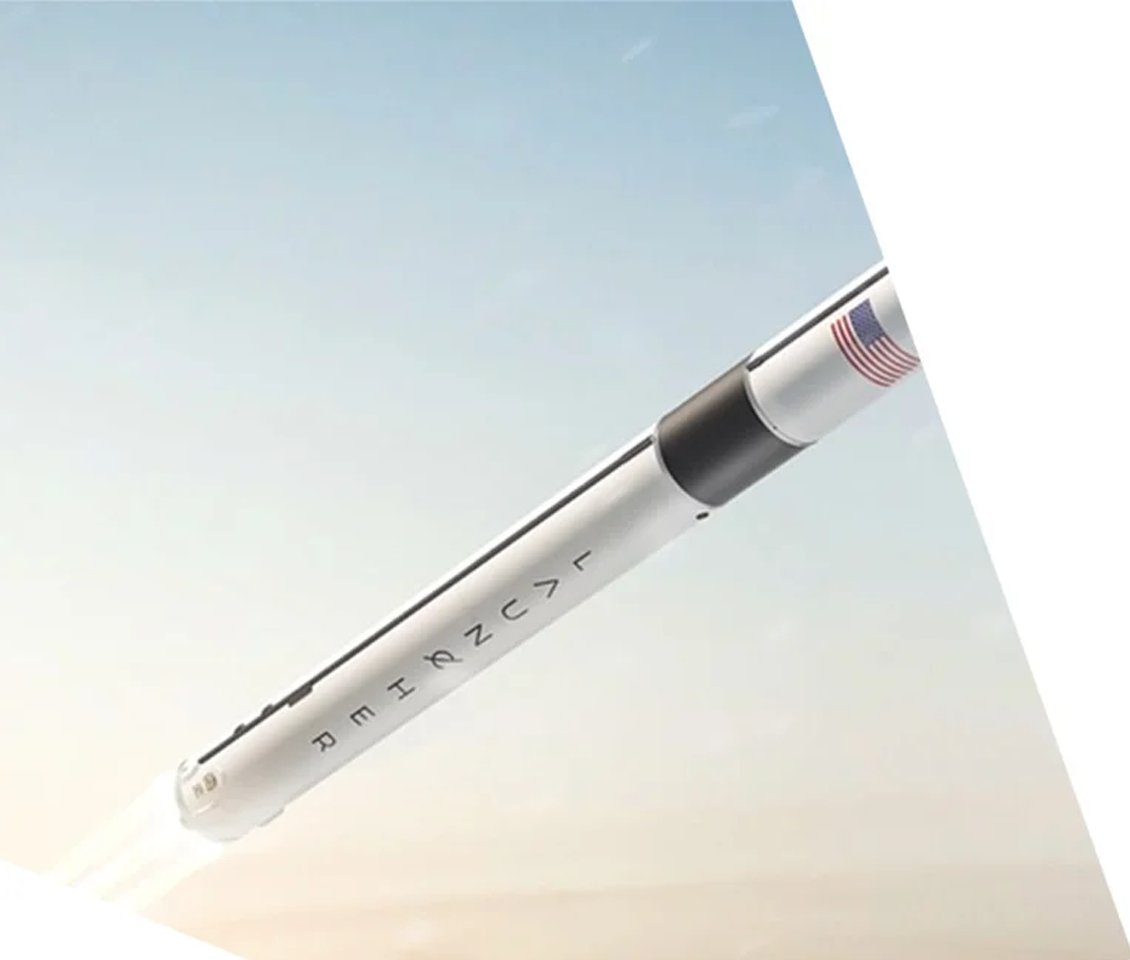

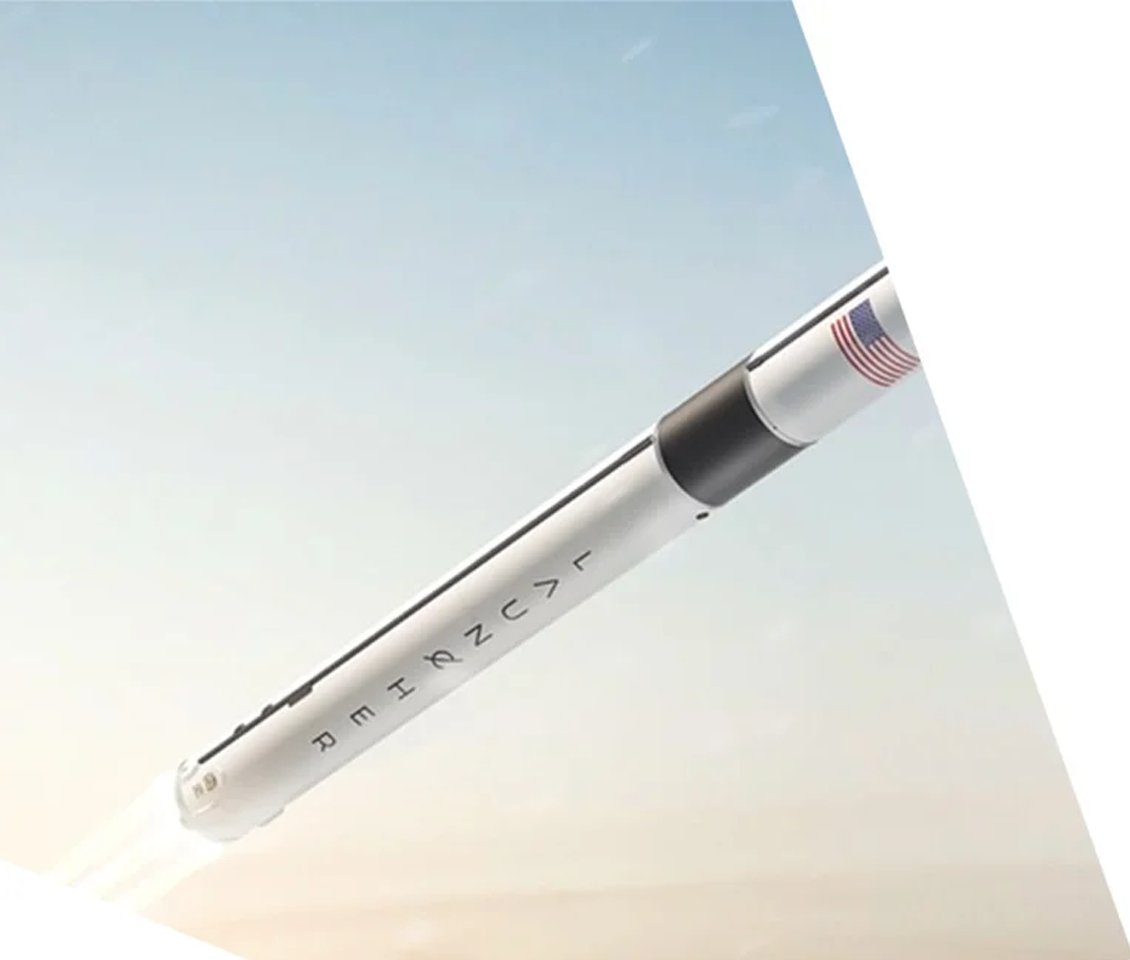

The World’s Largest Single Piece 3D Printed Rocket Engine

Use of Additive Manufacturing in Space Propulsion

New and improved technology has always been on the go for satellites and spacecraft. 3D printing has given rise to new designing and manufacturing possibilities for some of the most complex parts. The space industry is on a roll as more and more startup enterprises are interested in the industry and joining it. They know 3D printing technology is capable of meeting the stringent criteria of the aerospace industry while being cost-effective in the long run.

For more, please click here.

Daimler EvoBus's Production On Demand

Role of Additive Manufacturing In Efficient Spare Parts Logistics

Spare parts management is fraught with difficulties: extended lead times, overproduction due to low purchase quantities, logistics, and storage costs are common occurrences. By the time the part is required, the supplier may no longer be able to supply it. For example, buses and trains are typically in service for 20 years or more. So when there is a need for spare components, they are usually discontinued.

For more, please click here.