PA 1101

The white, light-transmissive, additively made parts at our facility have high impact resistance and don't break easily. Even under the most severe mechanical pressures, they do not splinter. They can resist high temperatures and have consistent mechanical properties over a wide range of temperatures compared to PA 12.

For more, please click here.

PA 1102 - Black

PA 1102 black is a laser sintering material made of a black polyamide 11 powder with. They have consistent black color, making them ideal for conspicuous regions vulnerable to abrasive wear. They also have high impact resistance and elasticity. They do not disintegrate even when subjected to extreme mechanical stress. They have superior temperature resistance and consistent mechanical qualities over a wide temperature range. It is a renewable resource-based substance made from castor oil.

For more, please click here.

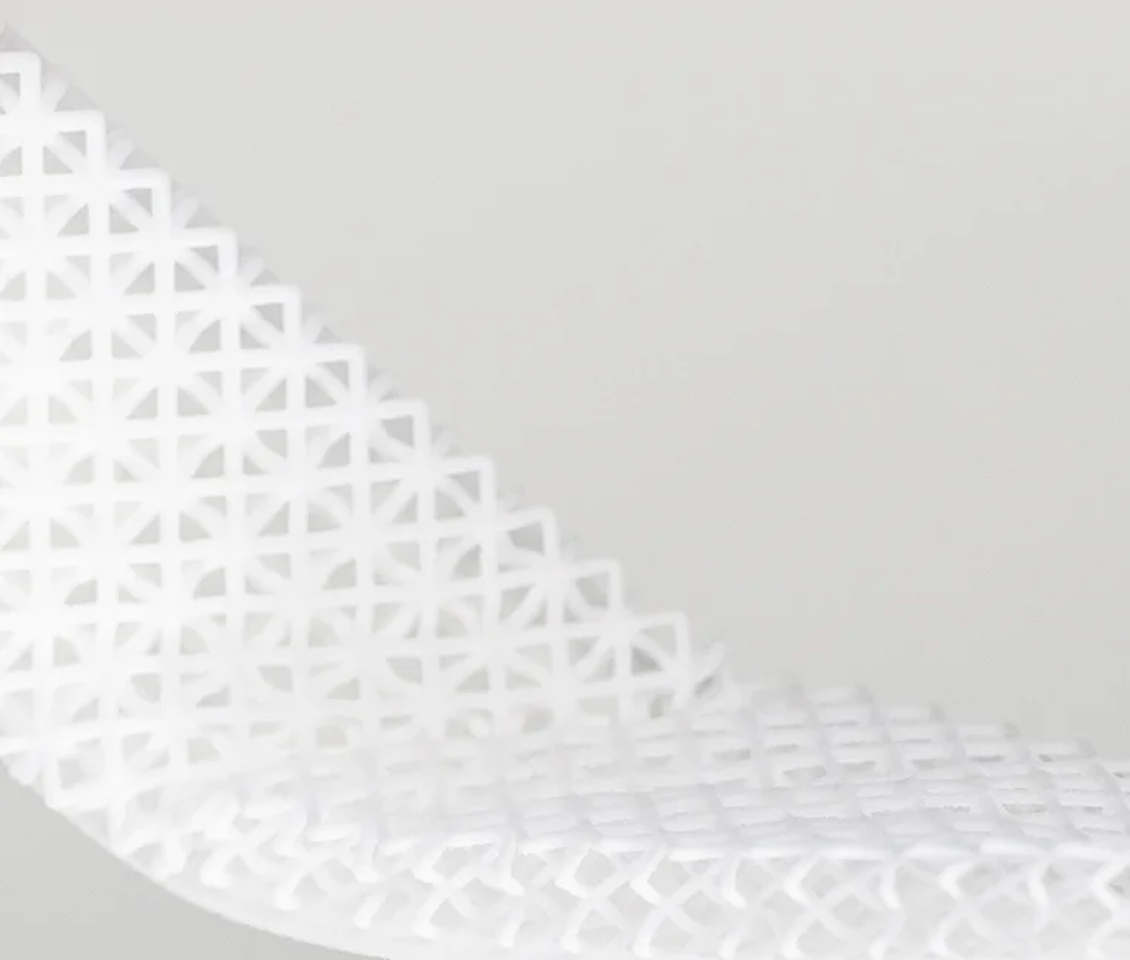

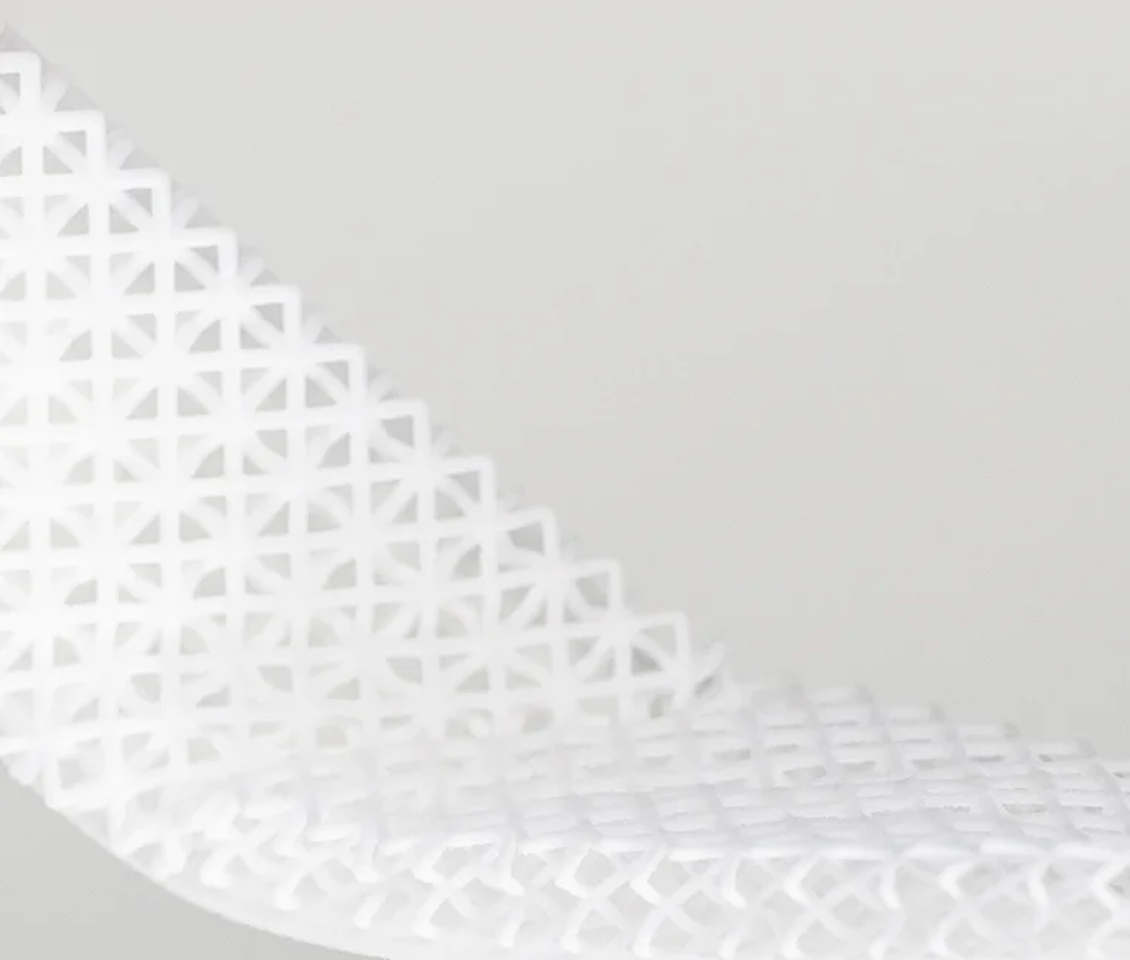

PA 2200

PA 2200 is a white powder-based polyamide with a well-balanced property profile, ideal for a wide range of applications. It's strong, robust, resistant to chemicals, and durable. It's also biocompatible and FDA-approved for food contact.

For more, please click here.

PA 2201

PA 2201 is a 12th-grade biocompatible polymide. It's pigment-free, but the parts made from this polyamide have a more transparent appearance than being white. It has outstanding chemical resistance, high strength and stiffness, high abrasion resistance, and detailed resolution, similar to PA 2200. It is also FDA-approved for food contact.

For more, please click here.

PA 2210 FR

PA 2210 FR is a white Polyamide 12 powder with a chemical flame retardant that is halogen-free. In the event of a fire, a carbonating covering forms on the part's surface, isolating the plastic beneath. A Blue Card has been issued by Underwriters Laboratories (UL) for PA 2210 FR 3D printing materials. It meets the UL 94 / V-0 flame protection classification for walls with a thickness of more than3 mm. It has numerous applications in electronic components, aerospace applications, and for parts that require increased flame protection

For more, please click here.

PA 3200 GF

The strength and elasticity of parts manufactured from this white polyamide 12 powder packed with glass beads are unmatched. They can withstand high temperatures and are resilient to harsh wear and tear. It is mainly used in car engines and as a deep-drawing tool molding material.

For more, please click here.

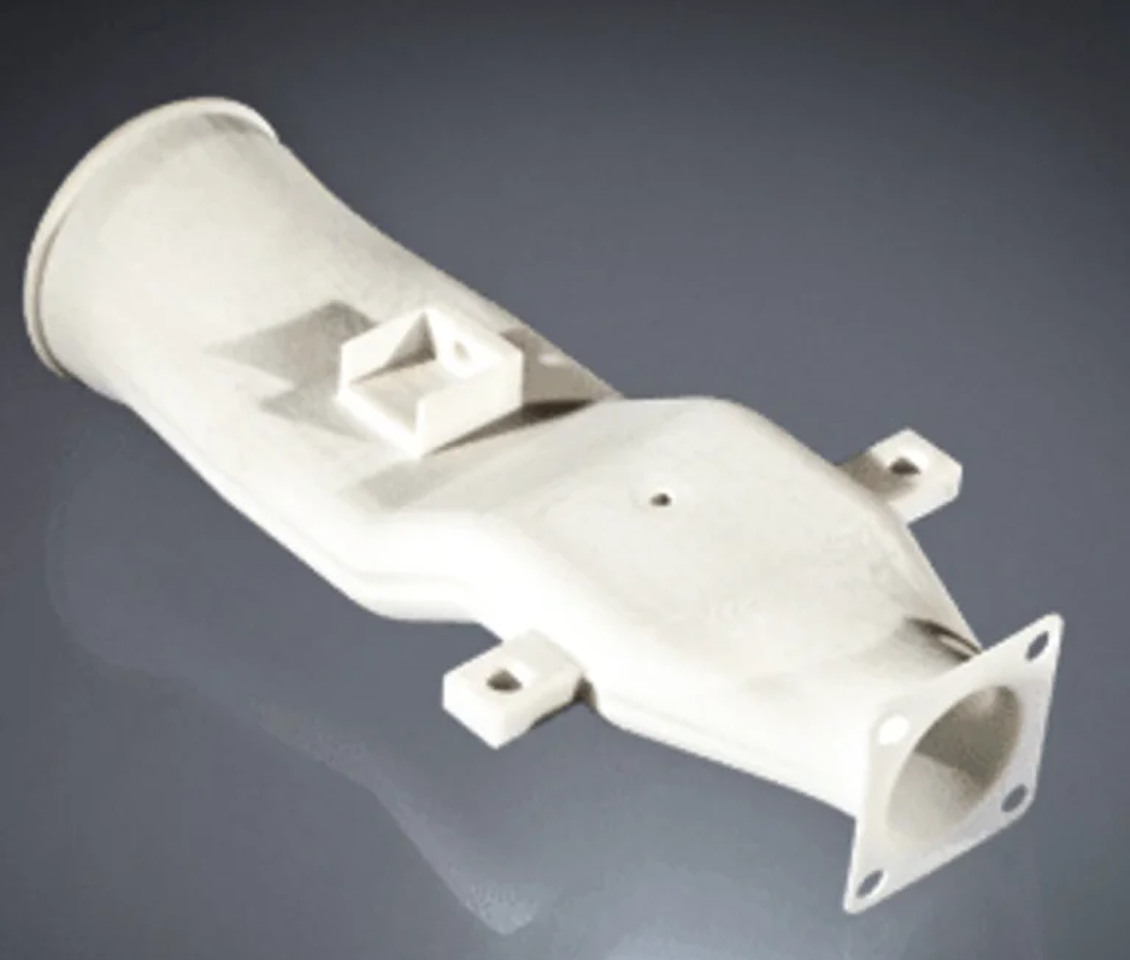

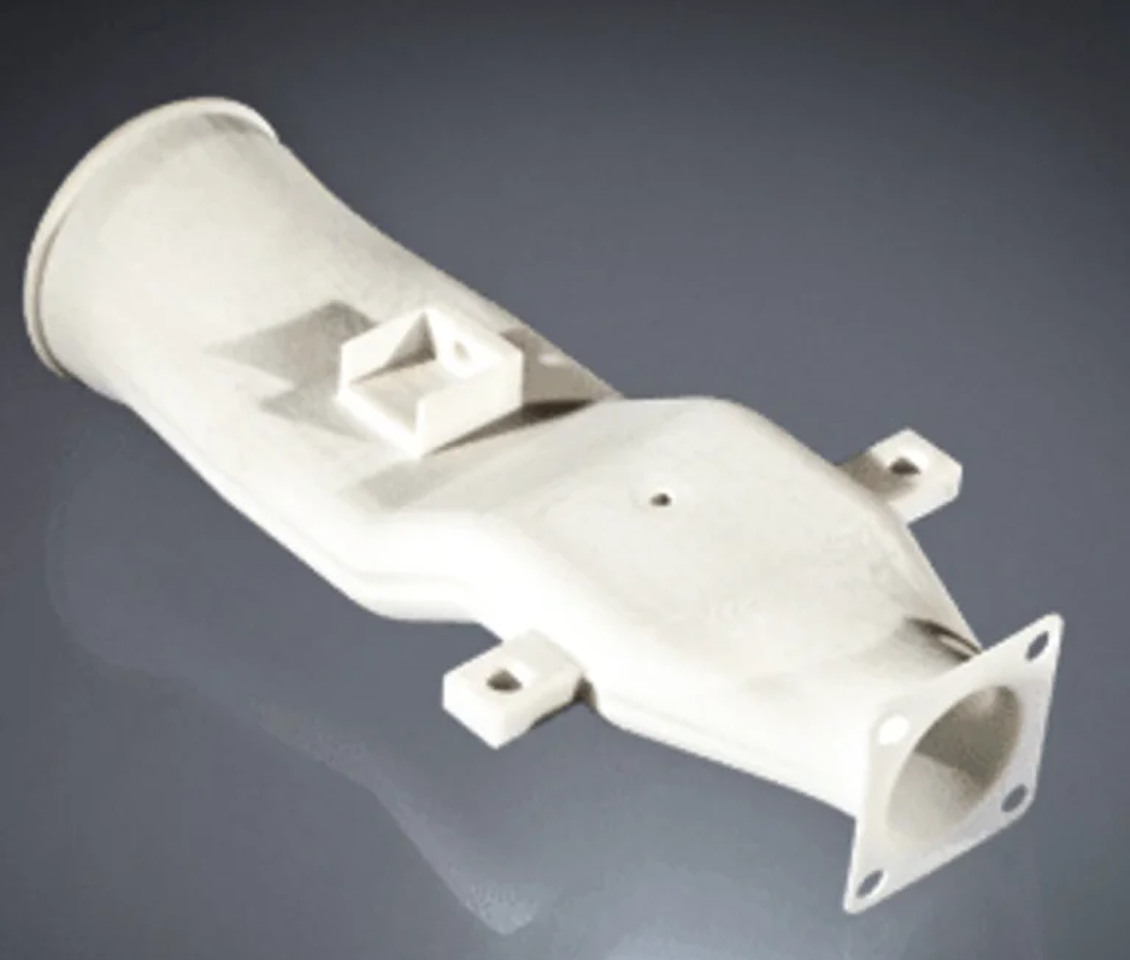

PrimePart FR (PA 2241 FR)

This white, polyamide-12-based material has a halogen flame retardant. It's cost-effective compared to other flame-retardant materials. The parts made additively, such as exhaust valves and ventilation ducts in airplanes, have high tensile strength and flexibility.

For more, please click here.

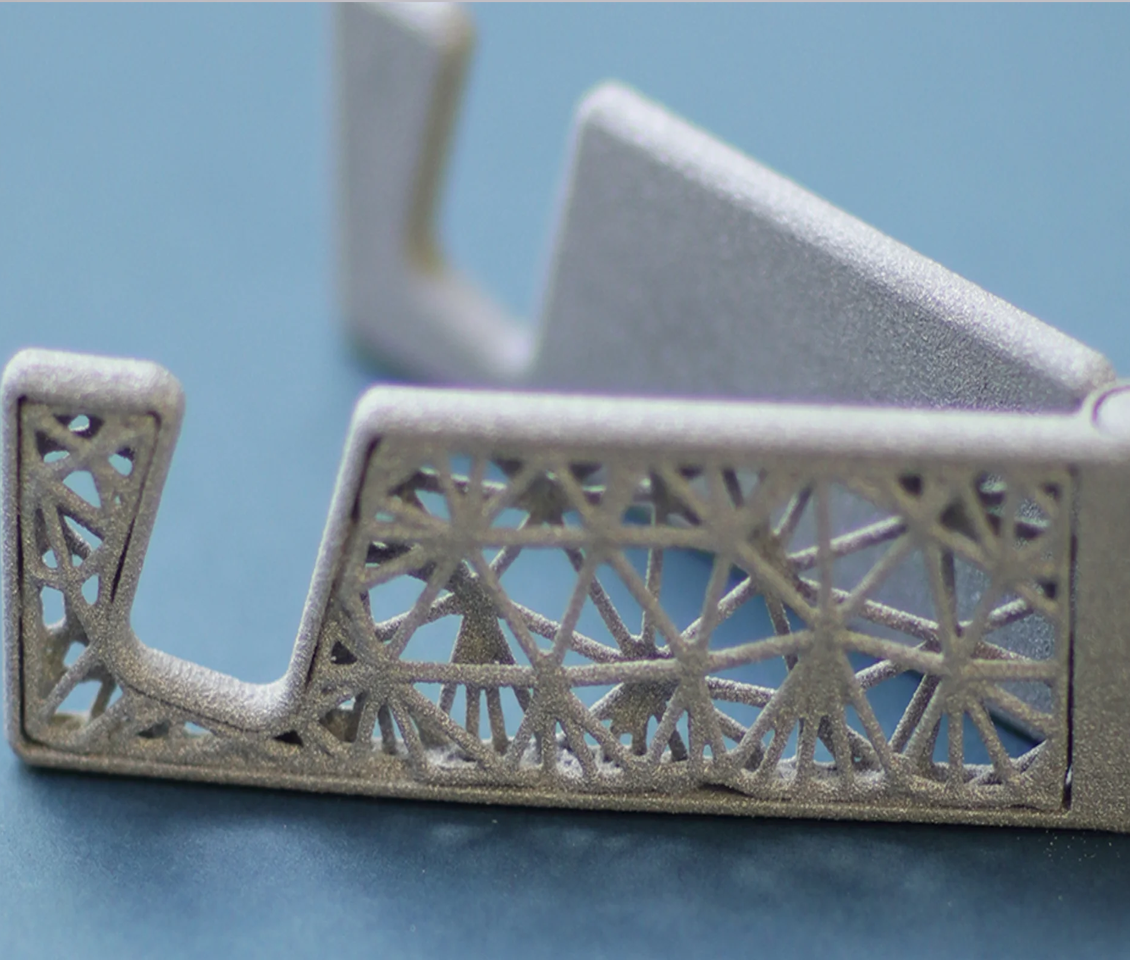

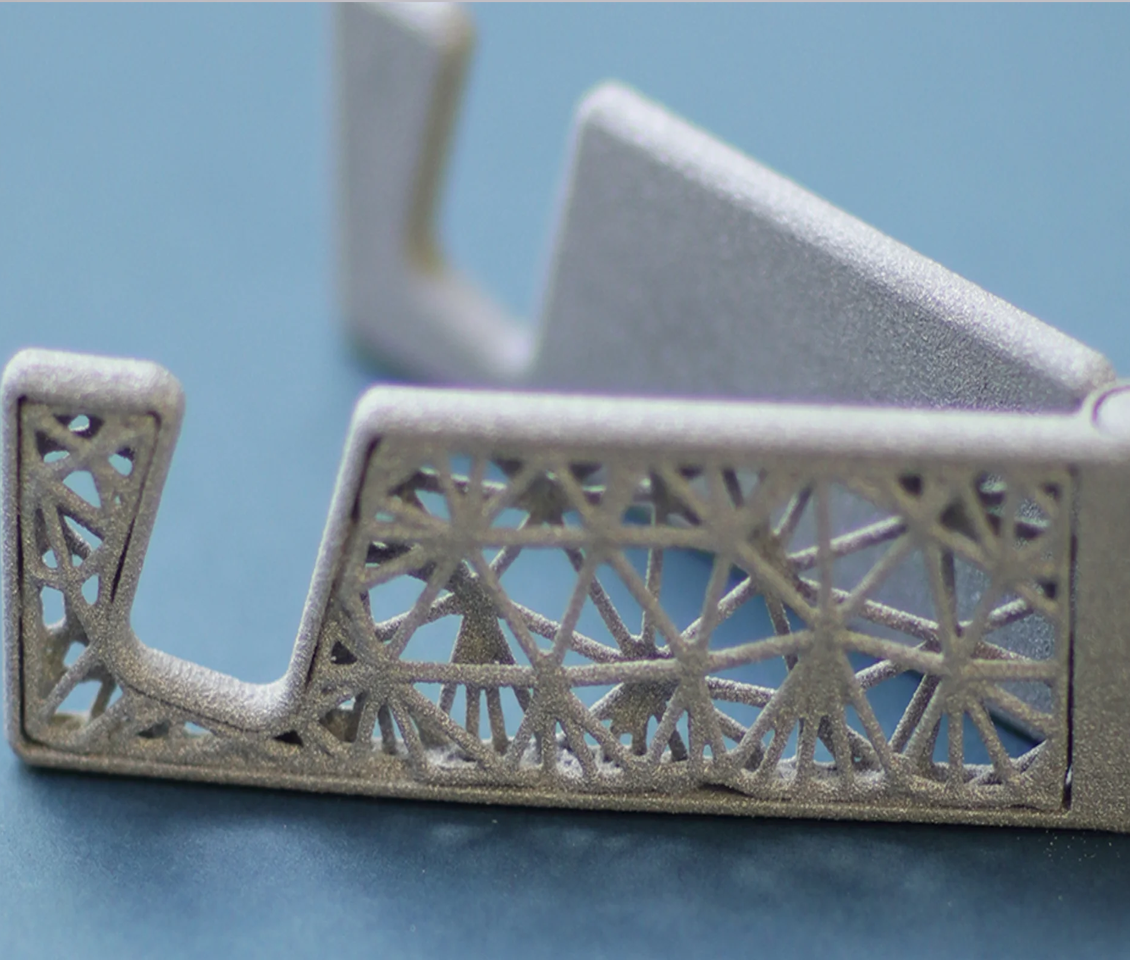

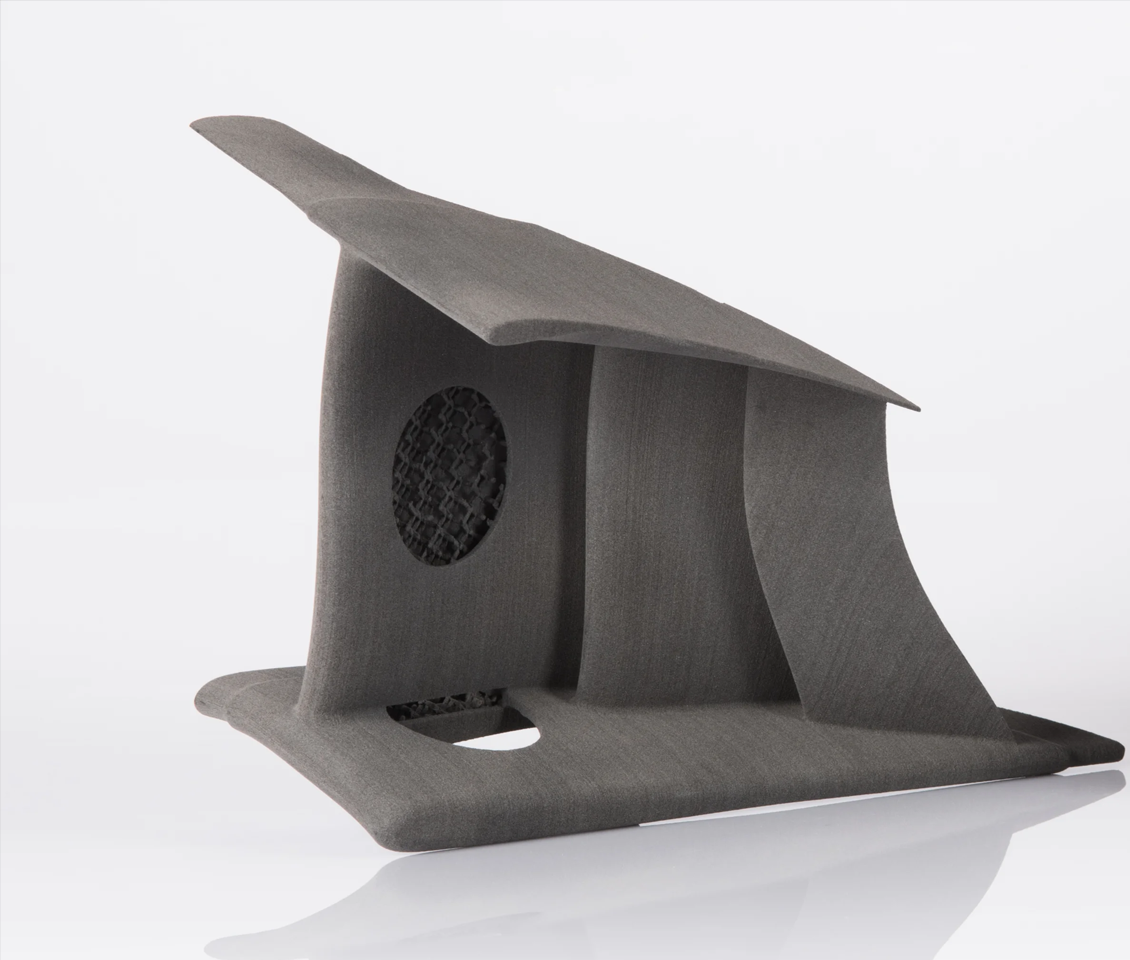

Alumide

A metallic look, high stiffness, and a variety of beneficial post-processing choices characterize this aluminum-filled metallic-grey polyamide 12 powder. Simple coating, polishing, or grinding can refinish the Alumide surfaces, making them look new. The aluminum filling's chip-breaking action makes machining a lot easier. Alumide® is highly resistant to high temperatures, showing exceptional dimensional stability. Therefore, Alumide-based components are ideal for functional applications at high temperatures.

For more, please click here.

EOS TPU 1301

This white material does not degrade in steam and hot water and has resistant to hydrolysis. It has great tribological qualities and is robust. Process parameters and varying part designs can significantly influence the degree of flexibility, which can even vary within the same part.

For more, please click here.

PrimeCast 101

101st PrimeCast is a grey-colored material made of polystyrene. It has a low melting temperature and outstanding dimensional precision, making the material ideal for investment casting.

For more, please click here.

FR-106

FR-106 is a white, polyamide-based material with flame retardants. Its unmatched strength and ability to be drawn into different shapes makes it ideal for complex geometries like load-bearing connecting pieces and housings.

For more, please click here.

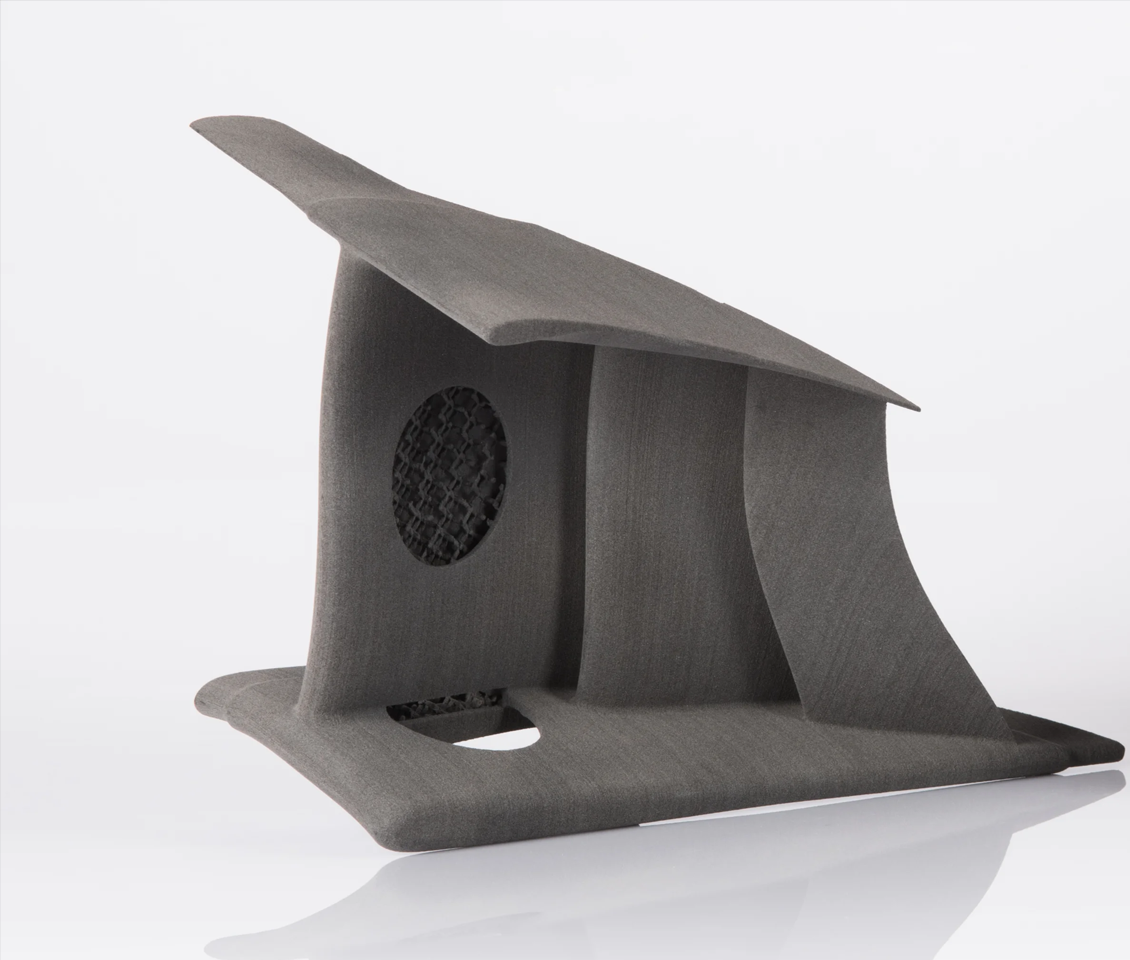

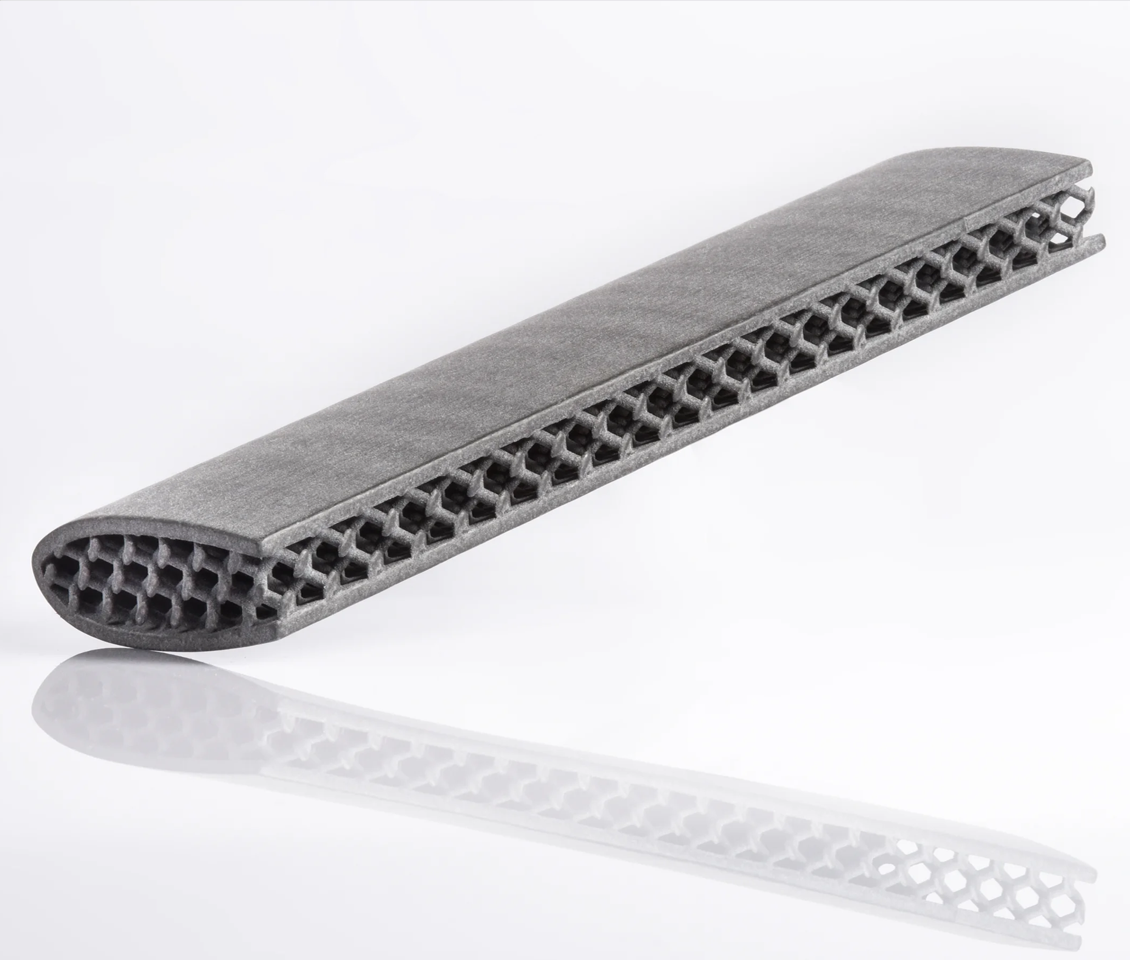

HP 11-30

HP 11-30 is a high-performance plastic manufactured from PA 11. Its strength is mainly due to the carbon fibers present in this material. It is impact-resistant, highly elastic, and electrostatically dissipative, ideal for additive manufacturing. This dark grey material exhibits similar mechanical properties in all three states as carbon fibers are present in the raw material.

For more, please click here.

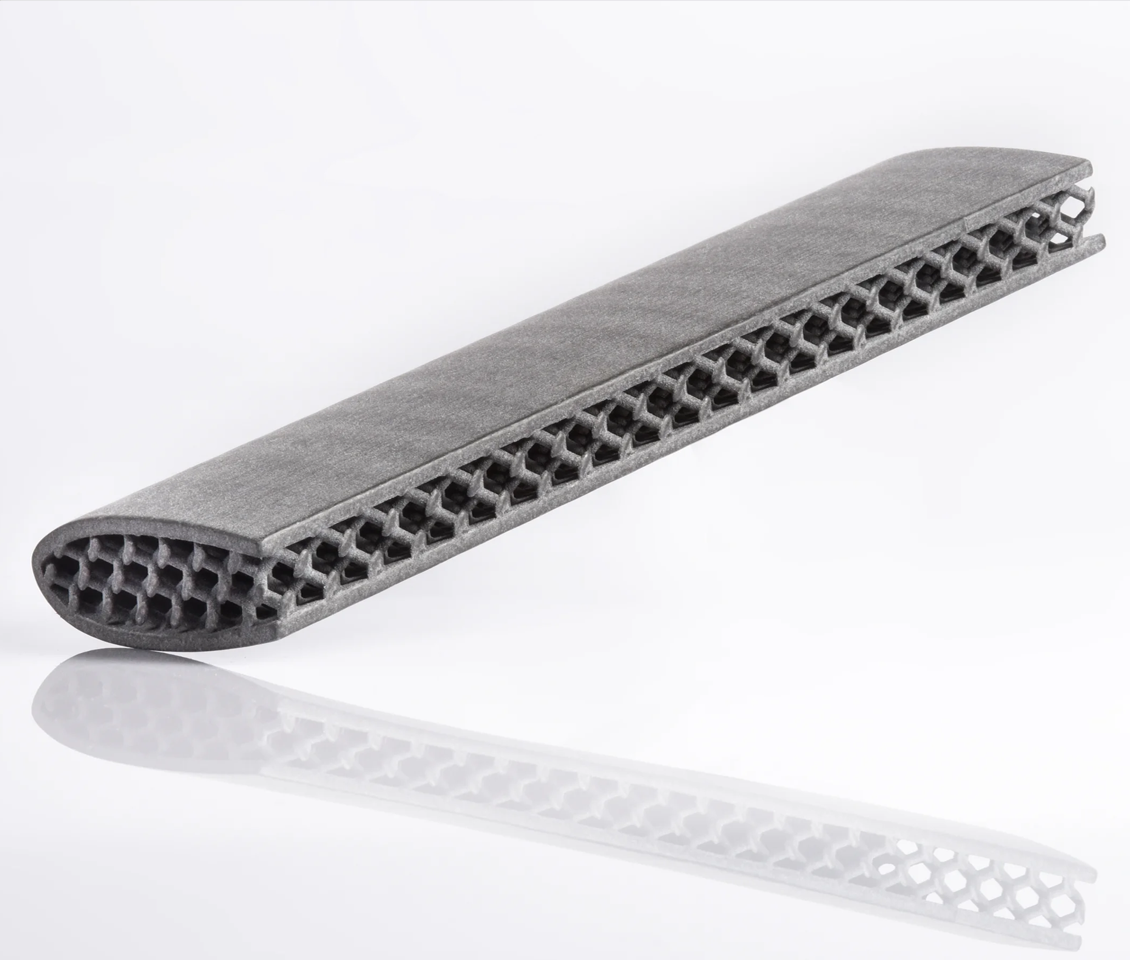

PA 640-GSL

PA 640-GSL is a dark grey, polyamide-12-based material that contains hollow glass beads and carbon fibers. It's a strong material that can withstand high temperatures. However, it is not very heavy, perfect for aerospace and athletic equipment.

For more, please click here.